Project description:

Our high-tech facility has the latest in computerized sewing, cutting and vinyl welding equipment. We are capable of sewing a wide variety of materials, including vinyls, nylon, cordura, nylon pack cloth, Nomex, neoprene coated nylons, netting, and canvas. All products are made to customer supplied specifications and prototypes are assembled for customer approval prior to production. During manufacturing each custom sewn product is inspected to ensure it meets our high quality control standards and customer specifications.

Notes:

- Project Name & Description

- Capabilities Applied/Processes

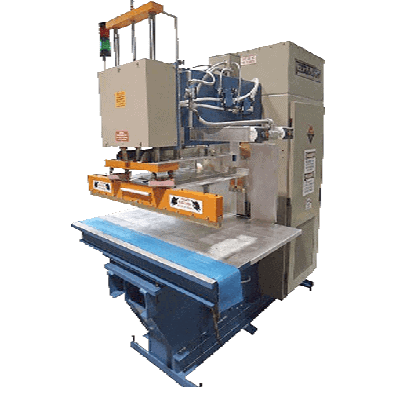

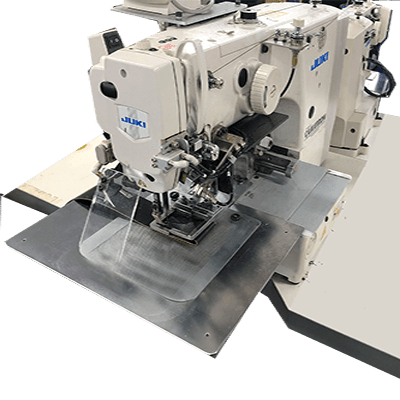

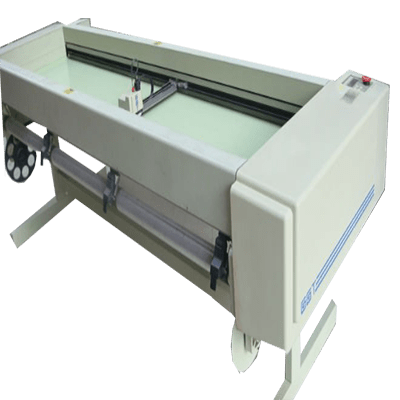

- Cut only, Labor Only, Cut and Sew. RF welding, die cutting, die press, stack cutting, single poly CNC cutting, heat cutting, cold cutting, embossing, heat transfers

- Equipment Used to Manufacture Part

- ½” Double needle, 1/4” Double needle, 1” double needle, single needle, sling machine, juki automatic box-x, RFL welder (heat sealer), CNC single ply cutter, grommet machine, plotter, die press, serger automatic heat cutter, stack cutter automatic cold cutter.

- Overall Part Dimensions

- Varies

- Tightest Tolerances

- ±.25”

- Material Used

- Woven fabrics, Vinyl, Vinyl mesh, Canvas, webbing, nomex, Kevlar, Polyester, Poly pvc, Cordura, Ballsitic, Laminated polyester, laminated ballistic, laminate, sunbrella, Aqualon, filter fabric, RFL, ethafoam, FDA vinyl

- Material Finish

- Laminated padded finish, urethan coated, vinyl coated, waterproof seal,

- Industry for Use

- Marine, Transportation, agriculture, manufacturing, food processing, auto, aerospace, retail and household.

- In Process Testing/Inspection Performed

- Volume

- 50-10,000

- Delivery/Turnaround Time

- Varies. 3 week average

- Delivery Location

- Urbandale, IA

- Standards Met